Brand:Sharelaser

Product origin:China

Supply capacity:200sets per month

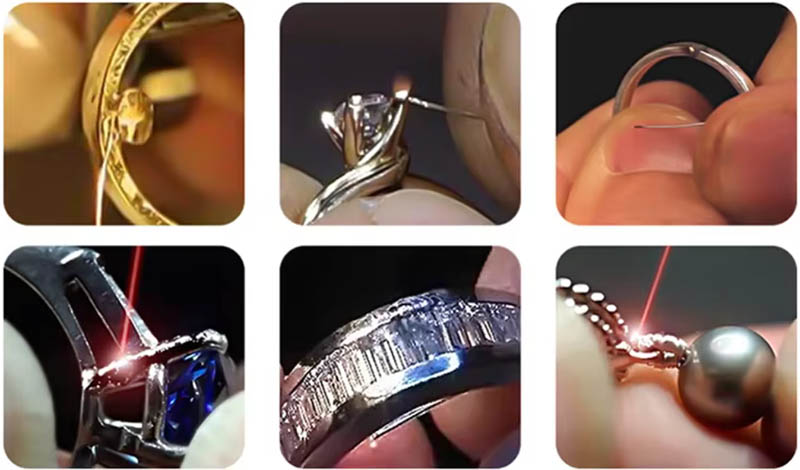

Laser spot welding is an essential part of the laser materials processing technology application, which belongs to heat conduction type. That is the surface of the workpiece heated by laser radiation, heat diffuses inside through heat conduction, by controlling the parameters of laser pulse width, energy, peak power and repetition frequency, the workpiece is melted to form a specific molten pool.

Advantages:

1. Automatic pumping, one-button operation, plug in the tube, enter the password, automatically add water.

2. The microscope is displayed synchronously with the CCD, very convenient for observation.

3. Compact design, saving space in the workshop or studio, and convenient transportation.

4. Air cooling fans reduces heat and maintenance costs.

Application:

The laser spot welder is applied to jewelry ornaments manufacturing, jewelry repairing, rings or bracelets resizing, gold and silver re-tipping, stone setting, eyewear welding or repairing, denture welding, small auto parts welding, etc. Generally, it is especially suitable for tiny target precision welding. It works on gold, platinum, titanium, silver, copper,nickel, aluminum, magnesium, stainless, etc.

Specification:

|

Input voltage |

AC220V±10% 50Hz |

|

Laser frequency |

1.0-15Hz |

|

Pulse Width |

0.1-10ms |

|

Spot adjustment range |

±3.0mm |

|

Maximum laser power |

60W/100W |

|

Machine power consumption |

≤2KW |

|

Aiming and positioning |

Microscope and CCD |

|

Ambient temperature |

≤30℃ |

|

Cooling method |

Water cooling |

|

Operation method |

Touch control |

|

Laser wavelength |

1064nm |

|

Display touch screen size |

7 inch |

|

Language |

Support English, Korean, Turkish, Arabic |

|

Machine size & Net weight |

510*295*395mm, 28Kg |

|

Packing size & Gross weight |

640*520*500mm, 40Kg |

Sharelaser supply laser marker,laser welder,laser cleaner at agent special price.

CEO: Tim Tang, Email: ceo@sharelaser.com

WeChat:+8613428733989